Motorcycle & Power Division was established in 2006, focusing on the R&D and manufacturing of large-displacement motorcycles, engines and transmission systems. Its 300CC-1200CC series power and vehicle products are mainly sold in China, Europe, America and Russia. The division has more than 260 employees, with a total investment of about 208 million RMB, covering an area of nearly 30,000 square meters, and an annual production capacity of 30,000 units. It has a complete R&D, testing, manufacturing, quality control, supporting, marketing and after-sales system, advanced technology, complete equipment and a sound quality system. In September 2019, it obtained the road motor vehicle production qualification issued by the Ministry of Industry and Information Technology.

The development team has 96 professional and technical personnel, including 5 senior engineers and 13 deputy senior engineers. Capable of product planning, styling, overall design, structural design, calculation analysis, electrical design, EFI calibration, trial production, inspection and testing, standard regulations, information management, etc. Now it has 1 invention patent and 42 utility model patents.

-

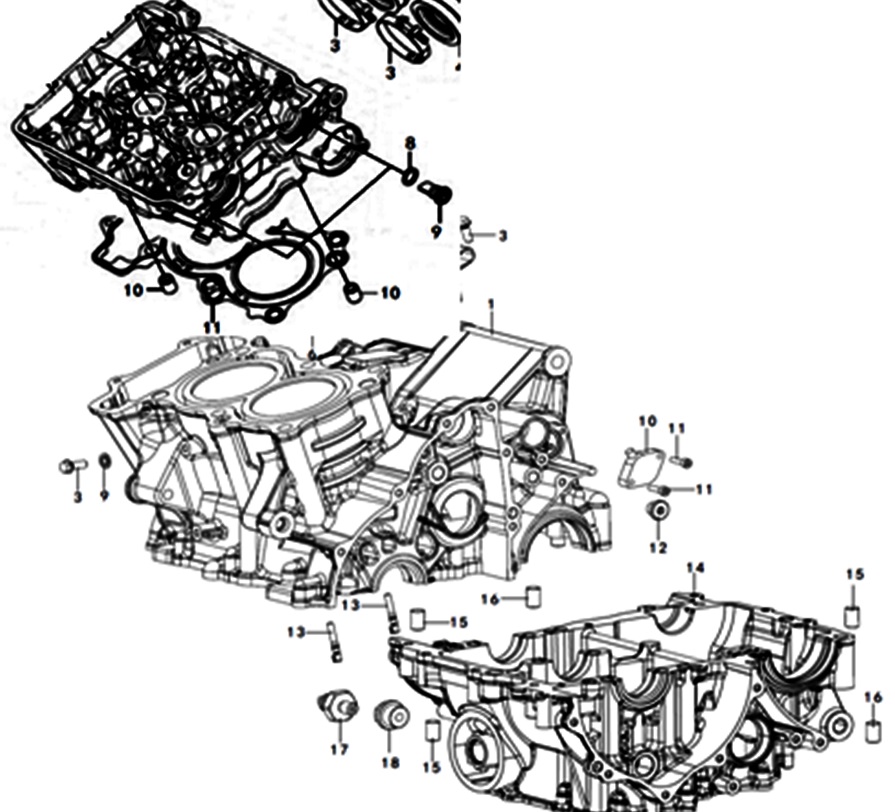

Engine design analysis

It can independently complete the overall design of the engine, optimize the cooling, lubrication, and intake/exhaust systems through flow field analysis and engine operation, and can use the calculation and matching of the engine dynamic balance system to realize the design and optimization of the crank connecting rod system. At the same time, it also has the ability of engine electronic injection calibration -

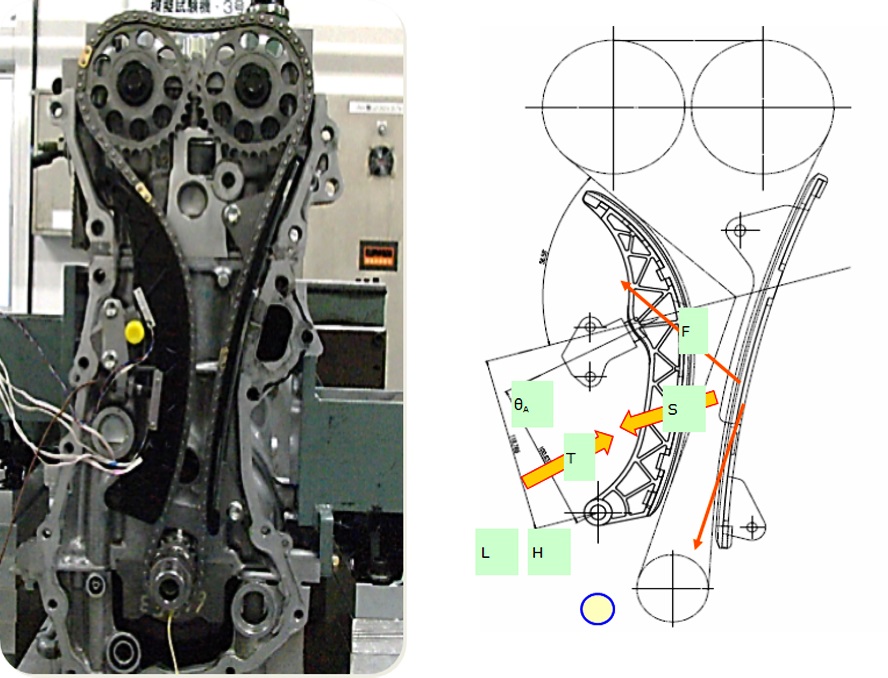

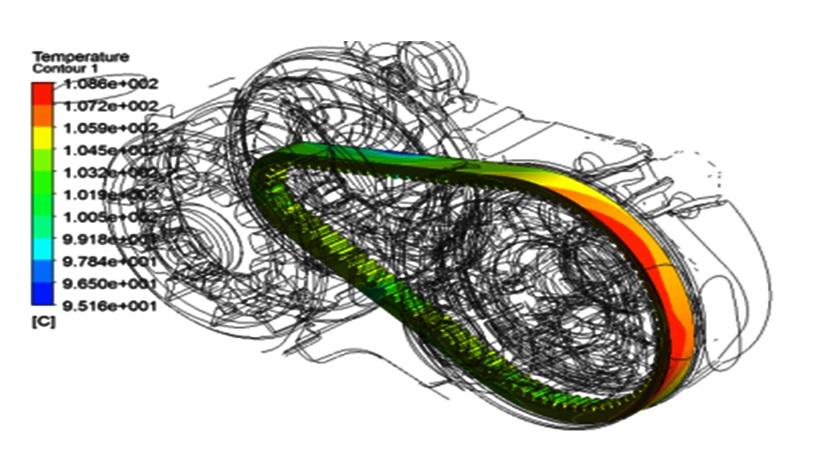

Timing chain design and analysis

Have the ability to independently complete the design and analysis of the timing chain, and complete the design and shape of the timing system and the timing tensioning system according to the actual engine operation -

.jpg)

Engine durability test line

Engine durability test line, with power torque, speed and fuel consumption testing capabilities, as well as monitoring the coolant and oil temperature

-

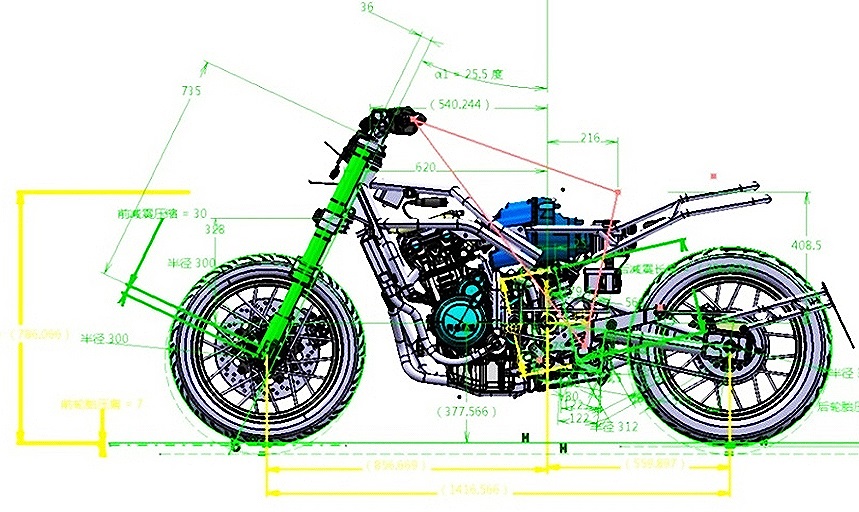

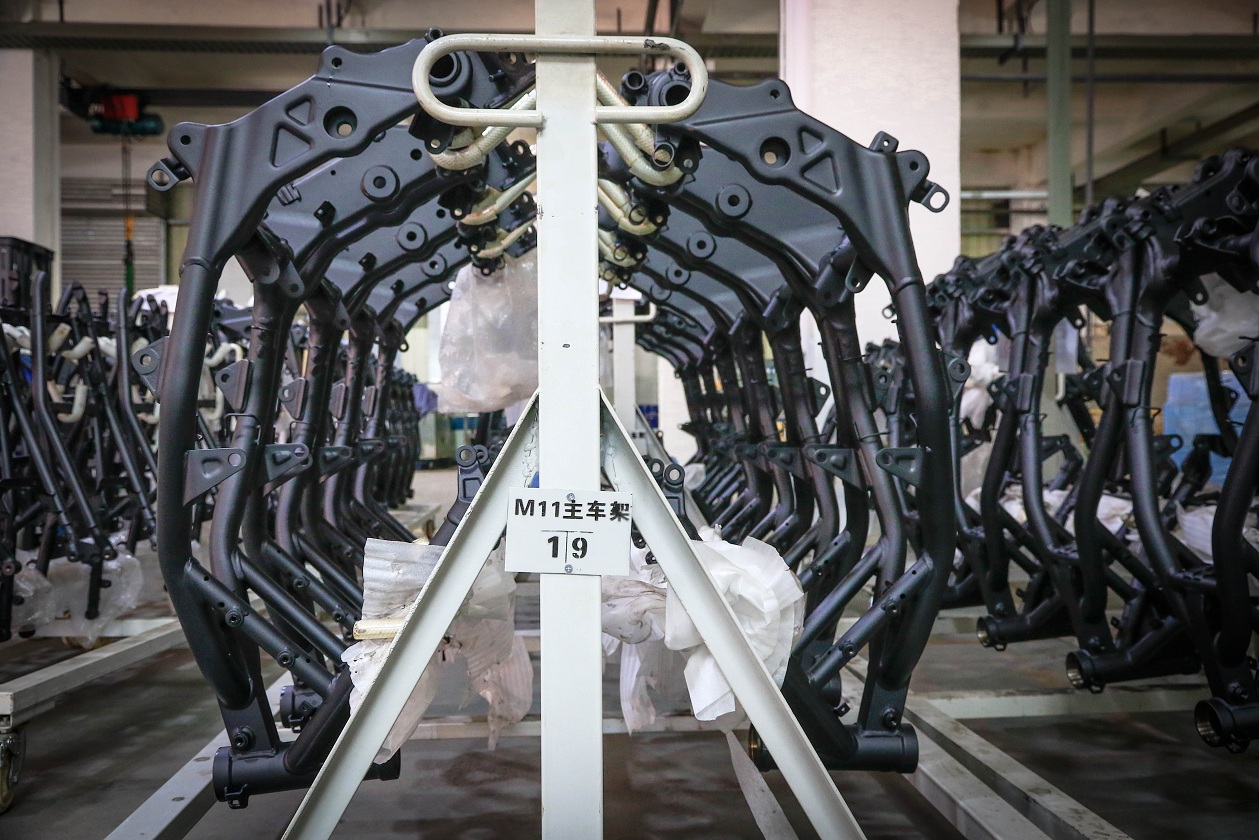

Motorcycle 3D frame model

Create motorcycle 3D frame model in accordance with the ergonomic principles and the latest motorcycle design concepts -

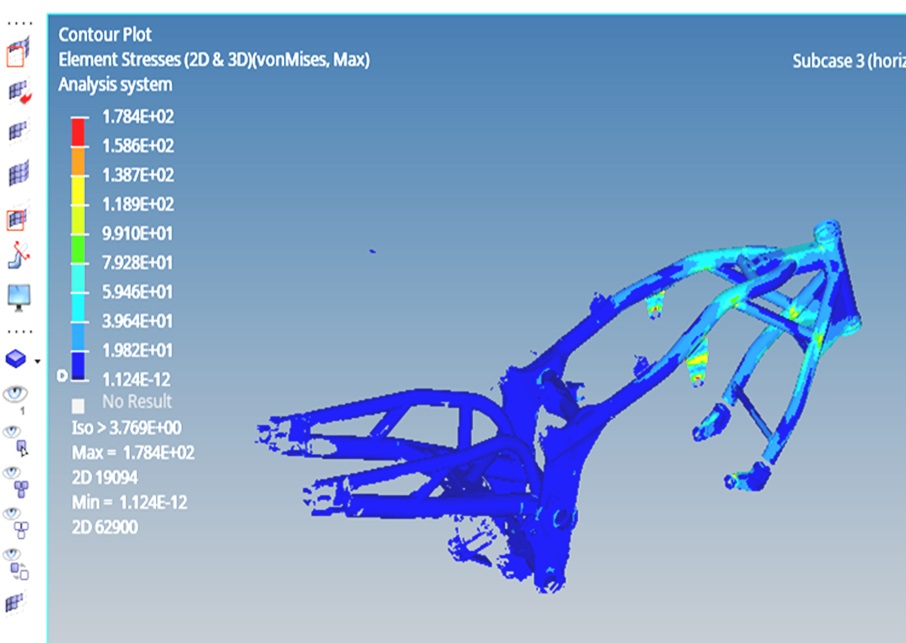

Frame Structure Analysis

Complete the frame structure analysis and realize the optimization of the vehicle performance, combining vehicle styling and lightweight design -

Chassis dynamometer & emission test lab (Euro V)

Chassis dynamometer & emission test lab (Euro V), possessing vehicle performance testing capabilities such as emissions under different working conditions, maximum speed, starting acceleration, and climbing ability

-

Transmission System R&D

Design and match CVT in accordance with customer's needs and actual uses -

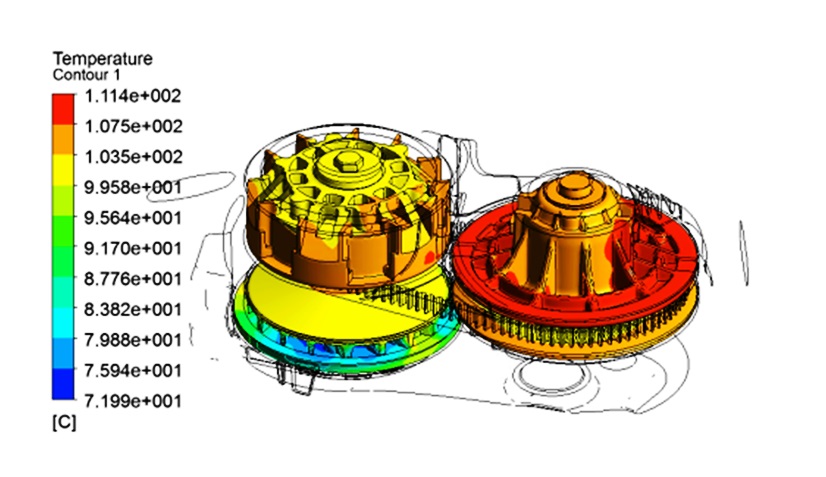

CVT Simulation Analysis

According to the actual working conditions, we can carry out simulation analysis for CVT cooling system, optimize CVT temperature field, and improve the reliability and life of CVT belt -

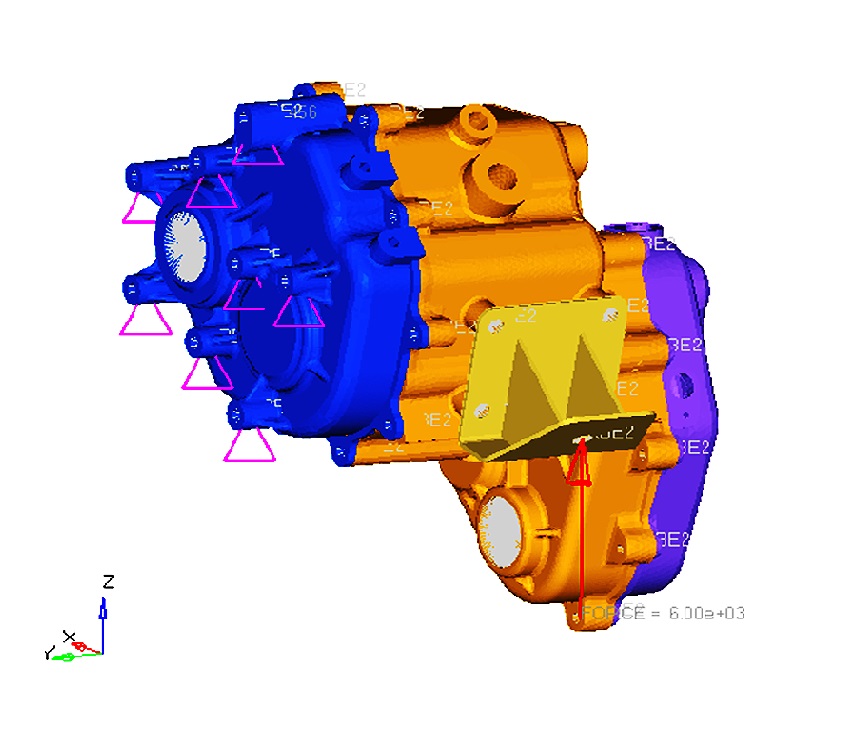

Gearbox Matching and Design

According to the customer's needs, we simulate, analyze and design the transmission system and optimize the parameters of each gear by using relevant software.

-

Motorcycle R&D

Motorcycle R&D, now the first model GK500 already released. -

Power R&D

Power R&D, a series of Engines from 200CC to 1000CC have been developed. -

Body design

Body design, now the first model GK500 already released. -

The motorcycle & power division has the production capabilities of machining, frame and rear fork welding, motorcycle engine and vehicle assembly, and packaging. It has 4 horizontal machining centers of various types, 20 vertical machining centers of various types, 2 CNC honing machines; Two manual welding lines, One robotic welding lines; One motorcycle assembly line, one engine assembly line, one assembly line for CVT and gearbox; one assembly line for engine and motorcycle.

-

Engine workshop

The engine machining workshop is equipped with machining capabilities for engine cylinder heads, cylinder blocks, cases and other products. CNC lathe, vertical machining center, horizontal machining center, drilling center, vertical honing machine, washing machine, laser marking machine.jpg)

-

Engine Machining

The engine machining workshop has machining capabilities for engine cylinder heads, cylinder blocks, cases and other components. CNC lathe, vertical machining center, horizontal machining center, drilling center, vertical honing machine, washing machine, laser marking machine.jpg)

-

.jpg)

Engine workshop

.jpg)

Engine workshop

.jpg)

Engine workshop

-

.jpg)

Engine Machining

.jpg)

Engine Machining

.jpg)

Engine Machining

-

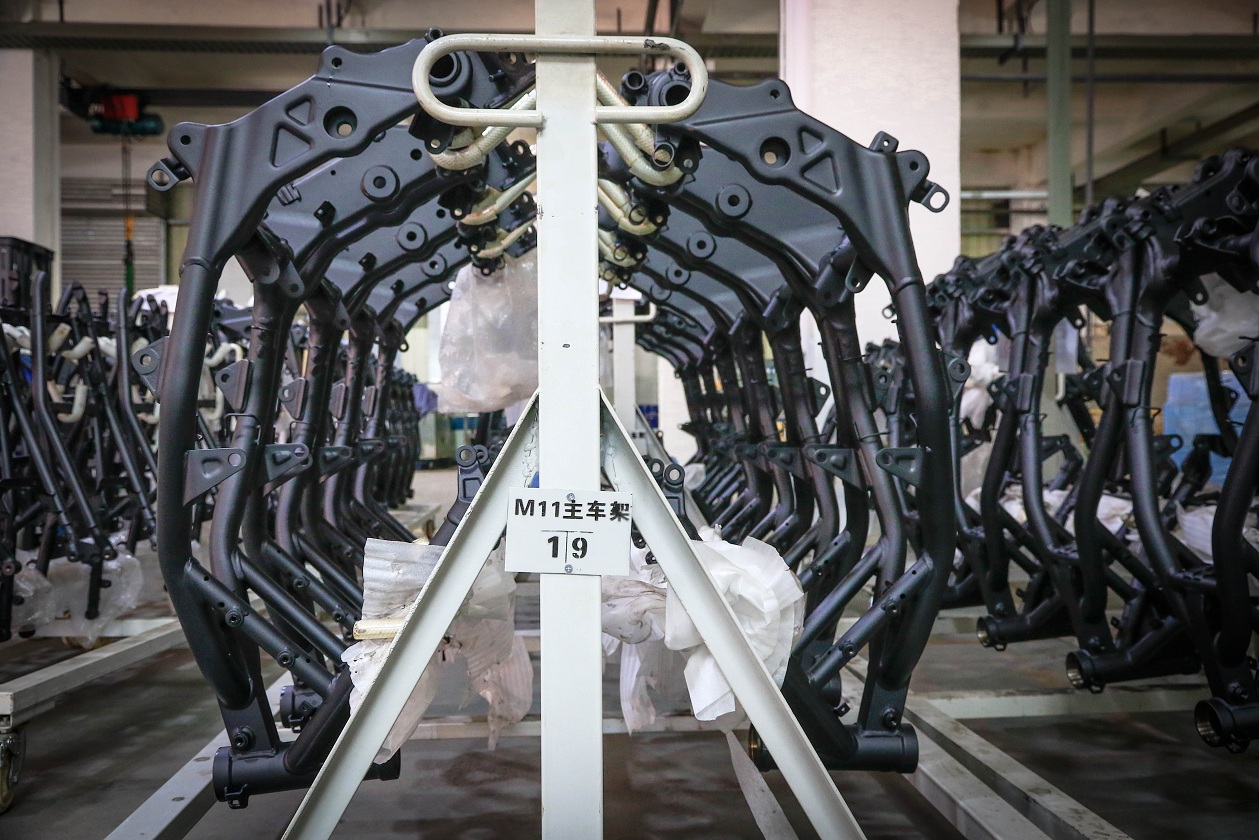

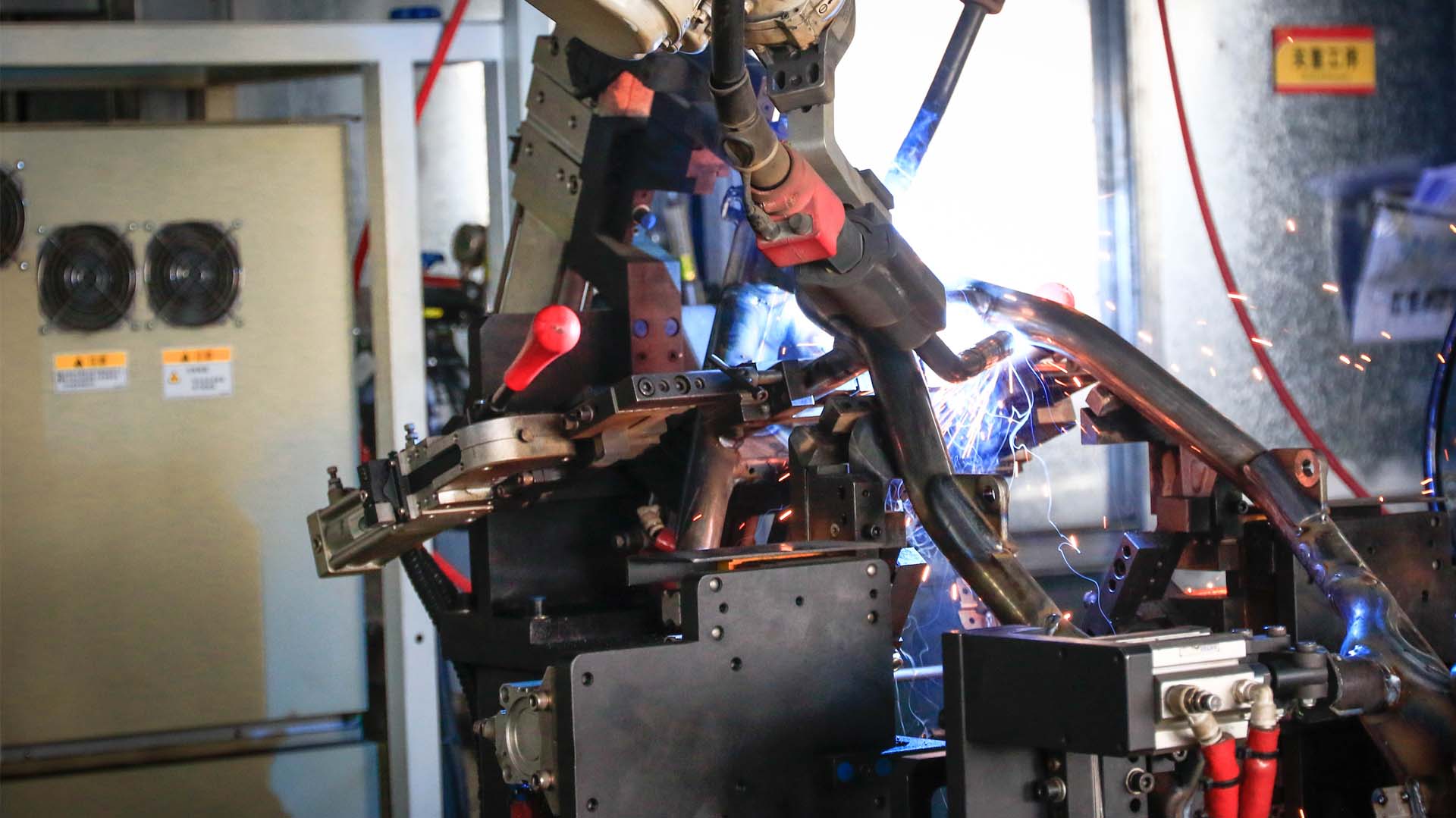

Robot welding & laser cutting

Welding production workshop, equipped with robot welding production line, has production capacity such as frame and rear fork.

-

Manual Welding

焊接生产车间,配备机器人焊接生产线,具备生产车架、后叉等生产能力。 Welding production workshop, equipped with robot welding production line, possessing frame and rear fork production capability.jpg)

-

Robot welding & laser cutting

.jpg)

Robot welding & laser cutting

.jpg)

Robot welding & laser cutting

-

.jpg)

Manual Welding

Manual Welding

.jpg)

Manual Welding

-

Motorcycle assembly line

Motorcycle packaging line Motorcycle packaging line,which can implement the same line packaging of motorcycles and spare parts.jpg)

-

Engine Assembly Line

With 6 offline testing benches, the engine assembly line is equipped with advanced technology, such as parts cleaning, heat-sealing assembly, quantitative fuel/oil filling, and leak detectors..jpg)

-

Gearbox Assembly Line

CVT and gearbox assembly lines, equipped with 6 offline testing benches, possessing the ability to test CVT & Gearbox together.jpg)

-

.jpg)

Motorcycle assembly line

.jpg)

Motorcycle assembly line

.jpg)

Motorcycle assembly line

-

.jpg)

Engine Assembly Line

.jpg)

Engine Assembly Line

.jpg)

Engine Assembly Line

-

.jpg)

Gearbox Assembly Line

.jpg)

Gearbox Assembly Line

.jpg)

Gearbox Assembly Line

-

Motorcycle packaging line

Motorcycle packaging line Motorcycle packaging line,which can implement the same line packaging of motorcycles and spare parts.jpg)

-

Engine Packing

The engine packing line implements co-line packing of engines and spare parts..jpg)

-

.jpg)

Motorcycle packaging line

.jpg)

Motorcycle packaging line

.jpg)

Motorcycle packaging line

-

.jpg)

Engine Packing

.jpg)

Engine Packing

.jpg)

Engine Packing

It has the ability to inspect the various standard items of the parts entering the factory, the performance inspection and running-in ability of the engine, and forced inspection ability of the complete vehicle off-line. It meets the domestic, European and American regulations and quality requirements, and the quality system is operating effectively.

-

.jpg)

Vehicle exhaust detection

Dual-idle emission detection and testing to ensure that the exhaust reaches the standard when leaving the factory and improve the product environmental protection coefficient. -

.jpg)

Vehicle offline test

Braking performance, axle load testing, braking force testing, ABS testing, instrument verification, acceleration performance testing, front and rear wheel consistency testing, light testing, horn sound level testing and other items testing capabilities. -

.jpg)

Offline test line

There are multiple offline test lines, and each vehicle is strictly tested and then packed before leaving factory. We have always maintained the most rigorous attitude towards quality issues.

-

.jpg)

Engine test

Engine test, check engine speed, fuel consumption, vibration, power torque, ensure that the vehicle has a strong heart -

Cylinder cover dry leak test

Test before the engine cylinder block is sealed to ensure the stability of the cylinder block -

.jpg)

Multiple test workshops

Multiple engine testing workshops ensure qualified quality, make the factory pass rate reach 100%, and ensure product performance to solve consumers' worries.

-

Comprehensive battery inspection

Microcomputer battery comprehensive parameter tester to test battery parameters. Ensure that each motorcycle battery is qualified -

Low temperature test

Stability testing of electrical components at low temperatures, in addition to electrical batteries and other measurements, we have also tested metal materials such as: metallographic microscope,Optical Emission Spectrometer, roughness profiler pendulum impact testing machine, universal testing machine , X-ray flaw detector: see machine plus quality for details -

Motorcycle comprehensive electrical tester

Comprehensive electrical testing, mainly testing the electronic components of the vehicle before assembly to ensure that the electronic system meets the standards

Motorcycle Poster

Motorcycle & Power Contact

- Nicole Li

Tel: +86-136 4764 6479

Email: nicoleli@gaokin.com - Dima Xiong

Tel: +86 152 1332 1195

Email: xxh@gaokin.com

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)